SemiProbe provided a turnkey and Integrated 200 mm Semiautomatic MEMS Probe System with an Olympus Metallurgical Microscope for a large Wafer Foundry.

Customer Requirements for their MEMS Wafer Prober System:

- Complete turnkey and integrated MEMS wafer probing system to test up to 200 mm microfluidic MEMS wafers over temperature

- Integrated solution had to provide a fully functional MEMS wafer probing and high magnification inspection capabilities using one platform

- Programmable Manipulators for electrical testing and fluidic dispense

- The devices needed to be heated and monitored from ambient to > 300 degrees.

- All test instrumentation, cables, connectors, and a Graphical User Interface (GUI) had to be provided

SemiProbe Solution:

Whole MEMS wafers, partial MEMS wafers, and individual die can be probed on the system using manipulators or a probe card. The devices are inserted in customized carriers and are held in place via a vacuum. The devices can be loaded on an adjacent bench or table and are easily inserted into and removed from the chuck assembly.

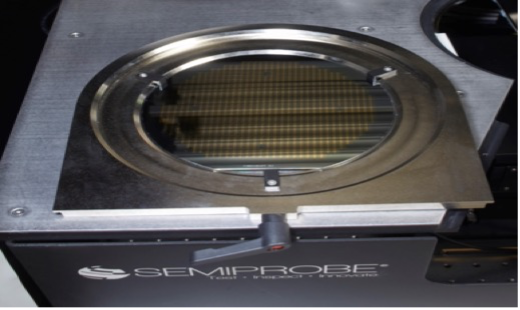

Complete MEMS Prober System - Showing Olympus Metallurgical / Biological Microscope Integrated with a 200 mm Semiautomatic Probe System

Complete MEMS Prober System - Showing Olympus Metallurgical / Biological Microscope Integrated with a 200 mm Semiautomatic Probe System

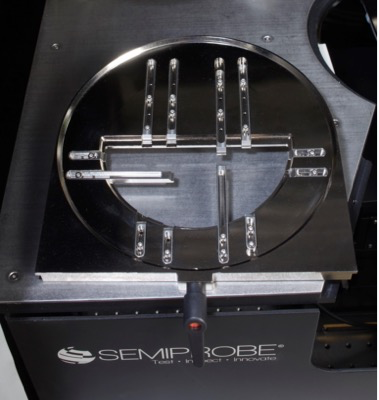

Programmable MEMS Manipulators with High-Frequency Probes

Programmable MEMS Manipulators with High-Frequency Probes

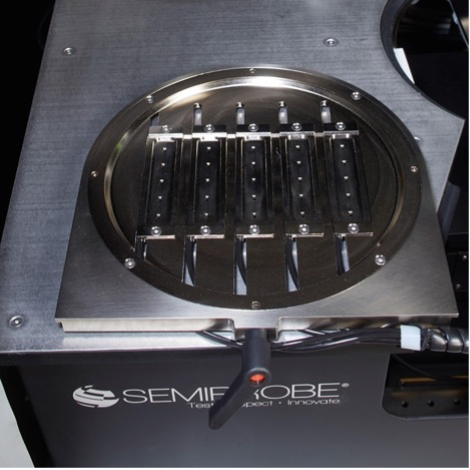

MEMS Wafer Carriers for Topside / Backside Testing

MEMS Wafer Carriers for Topside / Backside Testing

Partial MEMS Wafer Carrier for Topside / Backside Testing

Partial MEMS Wafer Carrier for Topside / Backside Testing

Individual Die Carrier for Topside / Backside Testing

Key MEMS Probe System Components:

- PS4L SA-8 semiautomatic probe system with programmable X,Y,Z, and theta stage

- Thermal Chuck System that operates from ambient to > 300 C

- Custom carriers for whole wafers, partial wafers, and individual die

- Customized Microfluidic Dispense System – input and output

- Four (4) programmable X,Y and Z manipulators with coaxial, triaxial and high frequency probe arms

- Probe Card Holder

- Test Instrumentation Rack and Cabling

- Customized Vibration Isolation Table, Dark Box and Dark Box Feedthrough Interconnect Panel

- Customized Graphical User Interface (GUI)