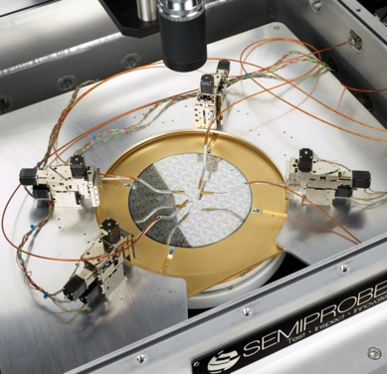

High Voltage Vacuum Prober Customer Requirements:

- A highly flexible, multi-purpose 300 mm manual vacuum probing system that would get used for device characterization in open air and under vacuum applications up 10 KV.

SemiProbe High Voltage Vacuum Prober Solution:

High Voltage Vacuum Prober

High Voltage Vacuum Prober

Triaxial Probe Arms

Triaxial Probe Arms

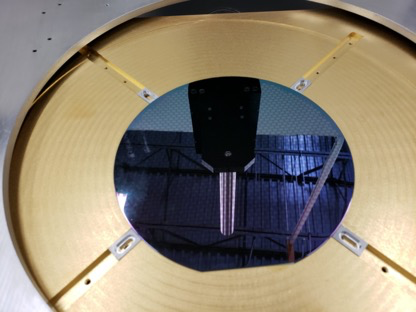

High Voltage Triaxial Vacuum Prober Wafer Chuck

High Voltage Triaxial Vacuum Prober Wafer Chuck

High Voltage Vacuum Programmable Manipulator Controls

High Voltage Vacuum Programmable Manipulator Controls

High Voltage Vacuum Prober Key System Components:

- Customized 300 mm vacuum prober chamber that included an oversized chamber door for easy wafer loading and unloading and a vacuum chamber top that could easily be removed to allow top access for open-air device characterization applications. Includes an Agilent vacuum pumping and MKS control system that would allow a vacuum level of 10-5 torr to be reached with the chamber top on.

- System was configured with a large travel microscope gantry and programmable long working distance optics that provides 300 mm of working distance and a variety of magnifications. Optics included a CCTV System.

- Four (4) programmable manipulators with coaxial, triaxial and high voltage (10 KV) probe arms. Manipulators can be controlled via software or the joystick controller. PC, Monitor, Keyboard, Mouse, and PILOT Navigator Software used to control the programmable manipulators remotely.

- A triaxial 300 mm gold plated chuck with a universal mechanical clamping mechanism that allows single die, partial wafers, and whole wafers up to 300 mm to be held. Chuck can be used in triaxial mode up to 3 KV or in coaxial mode up to 10 KV. Both lateral and vertical devices can be tested.

- Entire system mounted on a TMV Vibration Isolation Table (VIT) with casters and leveling feet

High Voltage Vacuum Prober Key Development:

- Programmable Manipulators

- Designed to be used in an open air as well as in a vacuum environment

- Designed to accommodate a variety of probe arms – coaxial, triaxial, kelvin, high frequency, high power (high voltage, high current), optoelectronic and more.

- Joystick controller and manipulators designed to be used on any probe system (analytical or production). No software is required to operate the manipulators.

- Designed as small footprint and based on the SemiProbe manual MA-9000 manipulator. Up to eight (8) programmable manipulators can be used on SemiProbe probe systems. Controllers are designed to handle up to four or eight manipulators.