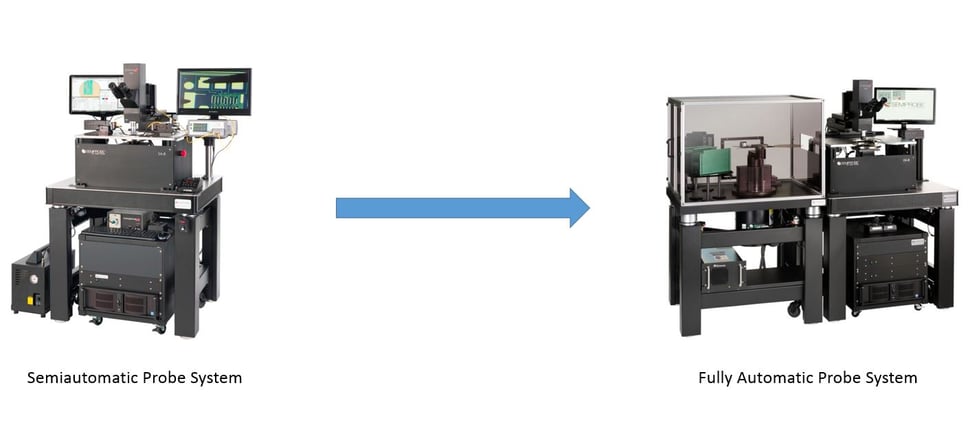

Until recently, upgrading probe systems was a difficult and strenuous process that could not be done in the field. Today, some manufacturers have created technology to enable users to field upgrade semiautomatic probe systems to fully automatic probe systems.

What is a semiautomatic probe system?

What is a semiautomatic probe system?

A semiautomatic probe system is manually loaded and unloaded. Auto alignment is available for most semiautomatic versions, which simplifies the alignment process. Essentially, the user loads the wafer, applies vacuum to the chuck and then clicks the align button. The system automatically aligns the wafer and then moves to the first device to be probed, often referred to as the home position. Prior to probing all die on the wafer, the contact position, the overdrive (scrub) and the index size all have to be set. After all those items are set, the user can save the settings and click the run button. All die on the wafer are probed, and, after the last die is probed, the stage moves to the load or unload position, which is normally the front-center location of the prober. The user has the option to load another wafer and repeat the process until all wafers have been tested.

What is a fully automatic probe system?

A fully automatic systemprovides the user the ability to load multiple wafers at a time into the MHU and then test uninterrupted for many hours without user involvement. A fully automatic probe system, also referred to as an automatic or production prober, can operate 24 hours a day/seven days a week. They are prmarily used when many wafers have to be tested or when devices are too fragile to be handled (manually loaded).

How do I convert a semiautomatic probe system to a fully automatic system?

To convert a semiautomatic probe system into a fully automatic probe system, two modules are added: a material handling unit (MHU) and auto alignment. The addition of these two modules allows the semiautomatic probe system to convert to a fully automatic one.

A MHU often provides the user the ability to load two cassettes of wafers into the cassette holders. In addition, the MHU usually has an end-effector, also referred to as a paddle, a pre-aligner and a safety enclosure. The end-effector is used to remove the wafer from the cassette, place it on the pre-aligner and then place it on the wafer chuck. After the wafer has completed testing, the wafer stage moves to the side where the MHU is mounted - normally the left side of the prober. The MHU moves to the unload position and then unloads the wafer from the chuck and then places it into a cassette. The user has a few options as where the wafer is returned to. Sometimes wafers are pulled from a slot in a cassette and then returned to the same location. Another option is to pull the wafer from one cassette and return it to the other cassette. It really is up to the user.

A pre-aligner allows the wafer to be precisely aligned to a certain mark – notch, flat, etc. and by doing this the wafer is precisely placed onto the wafer chuck. A wafer chuck is mounted to a stage theta movement and most have limited theta adjustment capabilities. Most programmable thetas have between eight and 10 degrees of rotation. Wafers often move within the cassette and without a pre-aligner the wafers often not be able to be auto aligned.

An MHU enclosure provides an environmental and safety enclosure, They often have access doors for the loading and unloading of cassettes and an opening to allow wafers to be passed from the MHU to the prober’s wafer chuck. MHU enclosures will have safety interlocks on them that shut the MHU down if a door has been opened while in operation. The MHU has moving parts and could injure a user if operated without safety interlocks.

When to use a semiautomatic vs a fully automatic prober depends on the application and budget. Sometimes semiautomatic probe systems are used for production applications. Fully Automatic probers are more expensive in comparison to semiautomatic ones but they offer the high volume capabilities (24/7).