Customer Requirements:

The customer wanted a highly flexible fully automatic 200 mm probe system for MEMS production. The system had to have the ability to handle wafers (100 mm, 150 mm and 200 mm), wafers mounted on frames and trays of die. The system had to provide the ability to be operated in manual, semiautomatic and fully automatic modes. The system had to operate with probe cards and manipulators.

- A PS4L FA-8 fully automatic probe system consisting of:

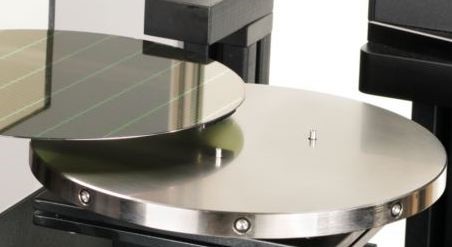

- A 205 mm x 205 mm programmable X,Y,Z and theta stage

- A 200 mm standard chuck with lift and alignment pins

- Vibration Isolation Table

- A compound microscope bridge and compound microscope movement (50 mm of X and Y and 50 mm of pneumatic Z)

- Compound Optics with a CCTV System

- Probe Card Holder and Manipulators (4) with coaxial probe arms

- Material Handling System consisting of two (2) cassettes, a pre-aligner, a dual end-effector (paddle and gripper), bar code reader and enclosure

To learn more about other Advanced MEMS Wafer Probers Click Here

To learn more about our complete Wafer Probe Testing Solutions go here.