Success Story – Canada

Customer Requirements:

- Complete turnkey Semiautomatic Double-Sided Probing (DSP) System with Test Instrumentation for testing optoelectronic devices in wafer, partial wafer and in die forms over temperature and in a dark environment.

- The system had to be configured to electrically test from the top of the wafer and optically detect an output from the bottom of the wafer.

- The optical detector is located underneath the wafer and had to be moved in X, Y and Z using a programmable manipulator.

- The devices needed to be heated and monitored from ambient to > 200 degrees.

- All test instrumentation, cables, connectors and a Graphical User Interface (GUI) had to be provided

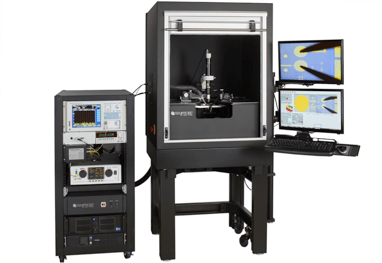

Turn Key DSP Semiautomatic Optoelectronic Probing System

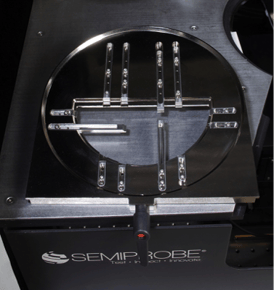

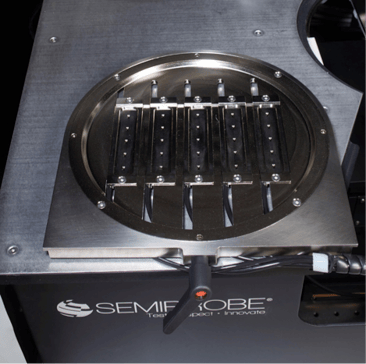

DSP Topside Probes and Thermal System

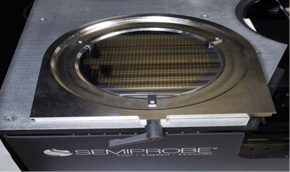

DSP Wafer Carrier for testing wafers 100 mm, 150 mm, and 200 mm.

DSP Carrier for Testing Partial (broken, fragments) Wafers

DSP Chip Carrier for Testing Individual Die

SemiProbe Solution:

Wafers, Partial Wafers and individual die can be probed. They are inserted in customized carriers and are mechanically held in place. The devices can be loaded on an adjacent bench or table and are easily inserted into and removed from the chuck assembly.

Key System Components:

- SA-8 semiautomatic probe system with programmable X,Y,Z and theta stage

- Double Sided Prober (DSP) chuck assembly with carriers for wafers, partial wafers and individual die.

- Zoom Tube optics with a CCTV System

- Customized thermal system with integrated thermocouples for temperature feedback

- Customized programmable backside detector unit for light optimization

- Test Instrumentation, Cabling and Rack

- Vibration Isolation Table, Dark Box and Dark Box Feedthru Interconnect Panel

- Customized Graphical User Interface (GUI)