Started in 2006 by semiconductor industry veterans with over 70 years of experience using, designing and building probe systems

Worldwide Customer Base – Universities, Government Labs and Corporations

As semiconductor industry veterans we’ve often seen how unanticipated testing changes required the purchase of a new system. The majority of the probe systems manufactured:

Have no or a limited upgrade path – example - increases in stage travel and chuck size often require a new system

Are single purpose systems with little flexibility

Are not designed to be upgraded in the field

Designed and patented a more modular probe system platform called the Probe System for Life (PS4L)

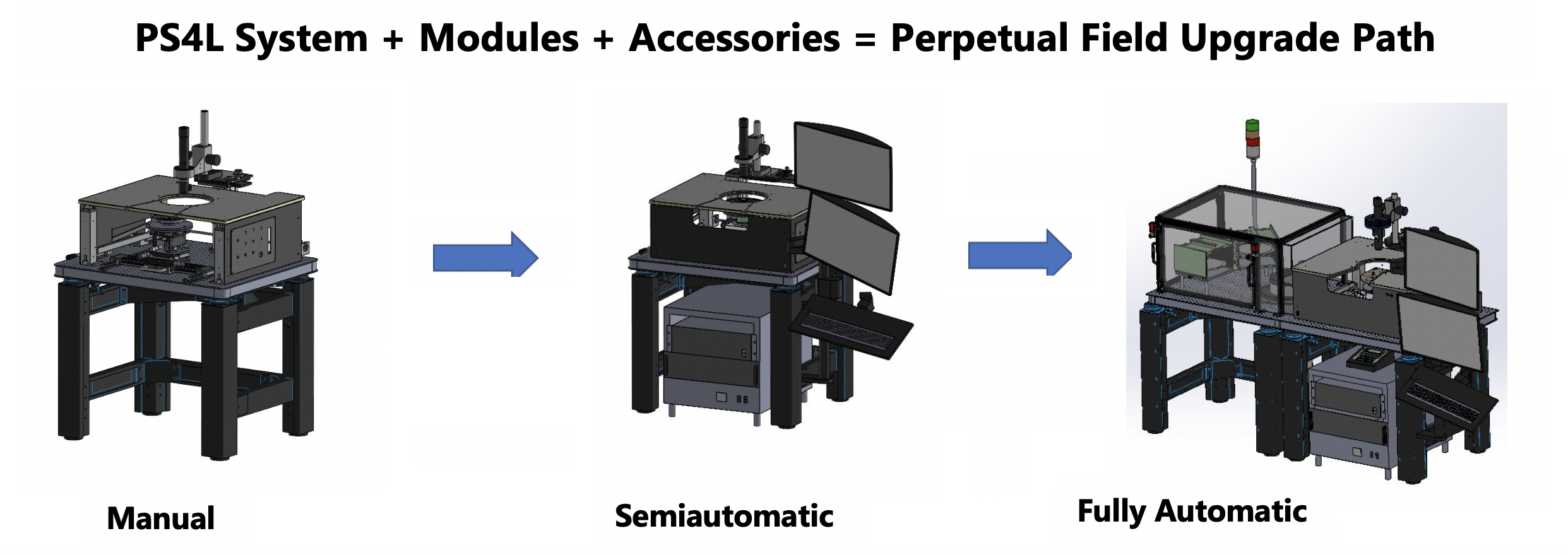

PS4L is a family of manual, semiautomatic, fully automatic and specialty probe systems with interchangeable components that allows a customer to start with a system that meets their application and budget and perpetually field upgrade it when their requirements change

Upgrades are performed at the customer location and at a fraction of the cost in comparison to purchasing a new system

Upgrade cost significantly reduced with a generous module upgrade program

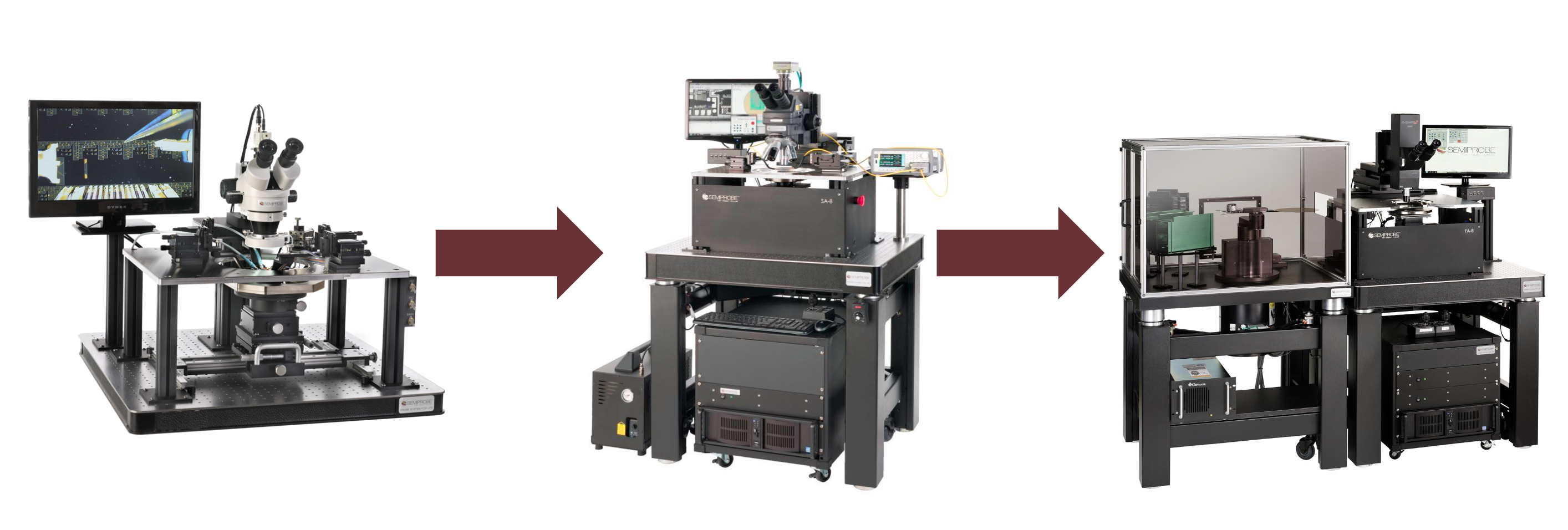

The PS4L Wafer Probe Testing Perpetual Field Upgrade Path

Manual Probe Systems can be field upgraded to Semiautomatic Probe Systems

Semiautomatic Probe Systems can be field upgraded to larger travel Semiautomatic Probe Systems

Semiautomatic Probe Systems can be field upgraded to Fully Automatic Probe Systems

Fully Automatic Probe Systems can be field upgraded to larger travel Fully Automatic Probe Systems

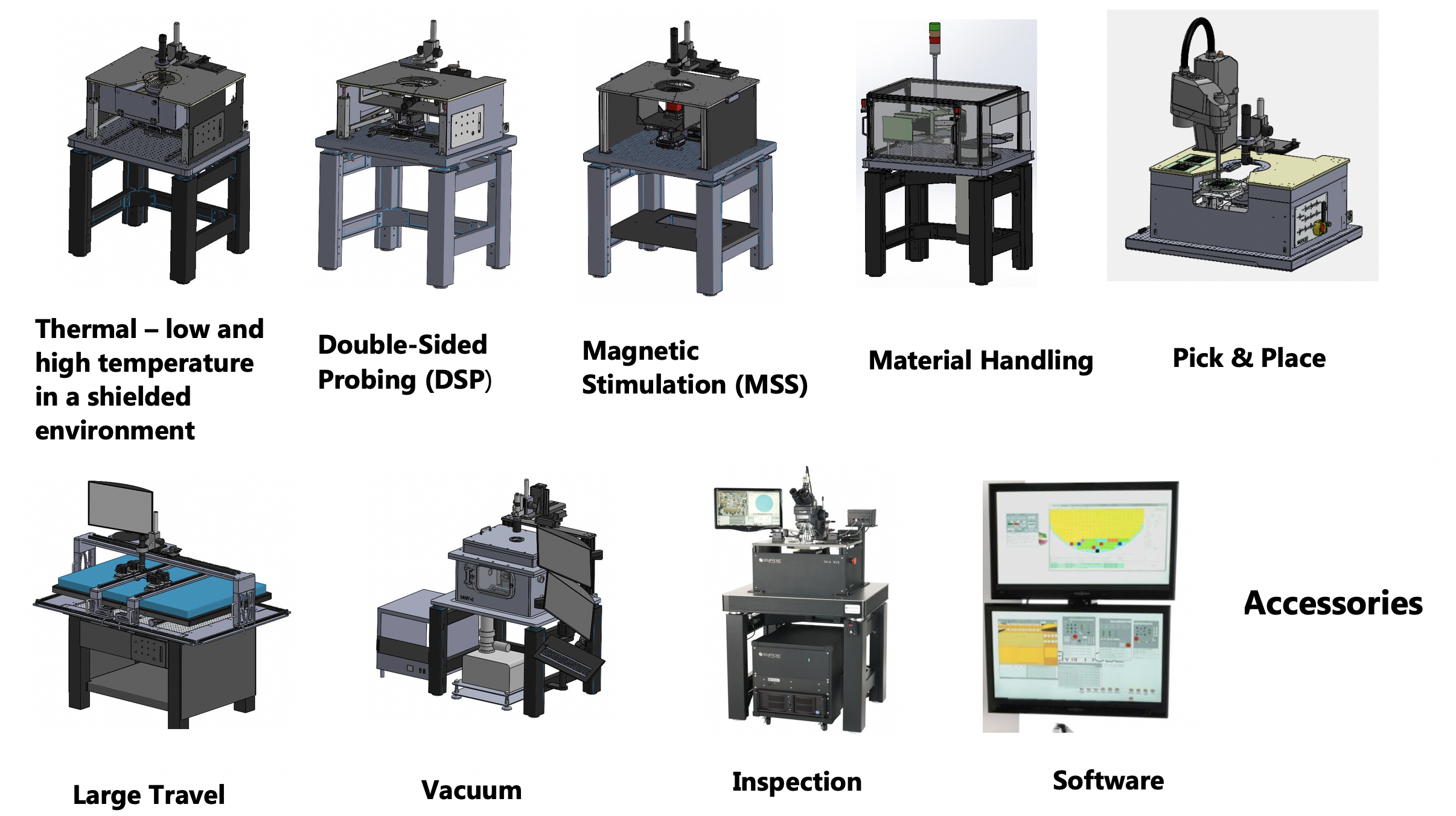

Modules can be added when required

Modules can be initially sold as an integrated application specific probe system or added to your existing system at a later date when your requirements change

Modules are added at the customer site at a fraction of the cost in comparison to a new system

New modules convert single purpose probing systems to multi-purpose probing systems

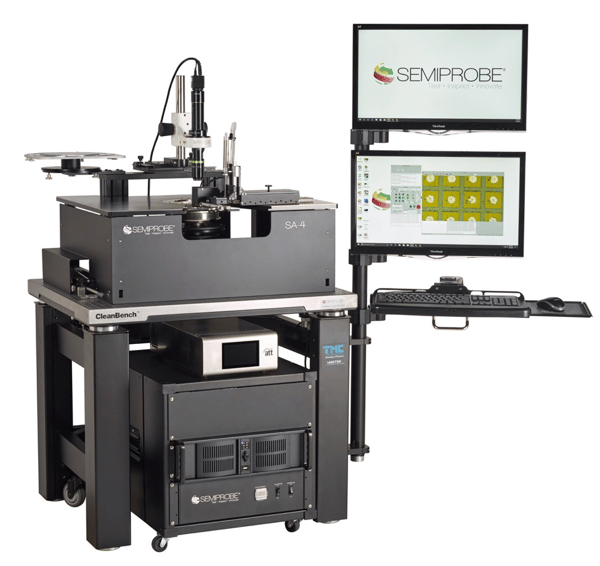

The World's First Fully Modular, Field Upgradable Wafer Testing Systems

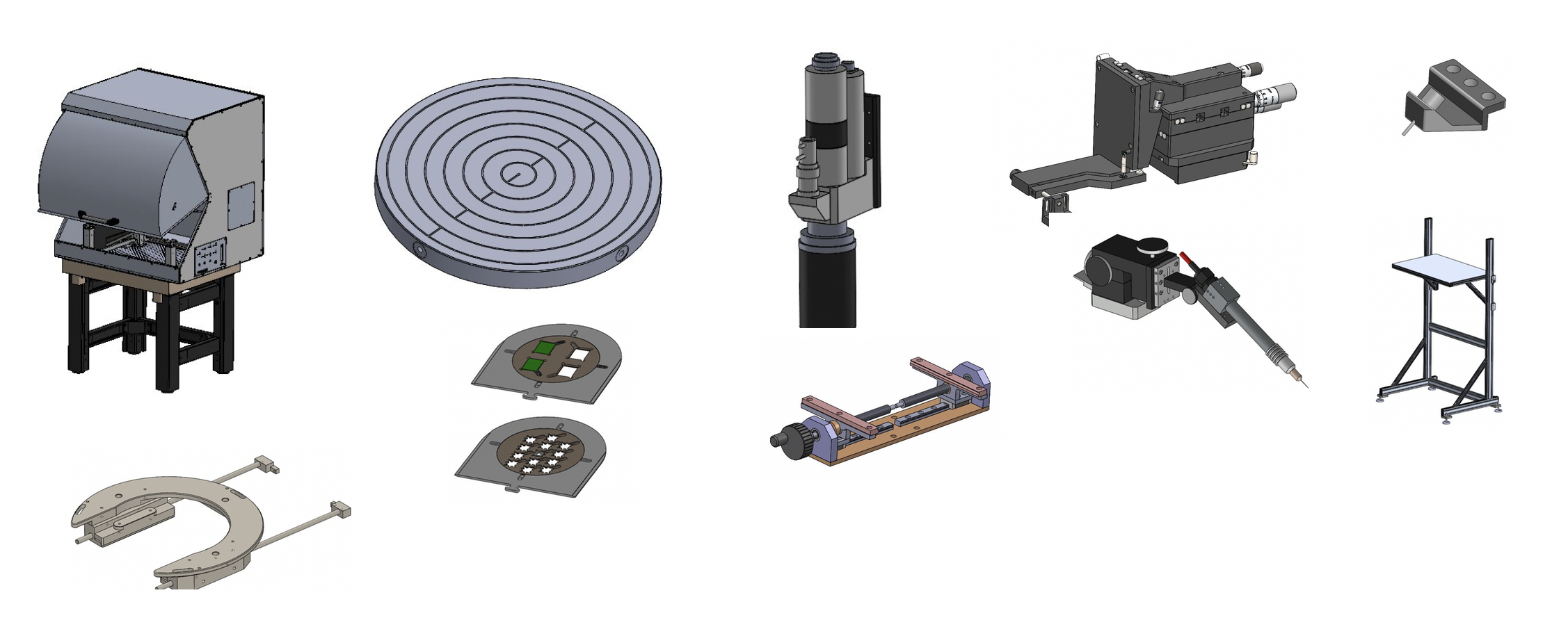

Many to select from that are application specific – dark boxes, light curtains, vibration isolation tables, chucks, manipulators, probe arms, probe tips, cables, connectors, probe card holders, packaged part holders, optics, CCTV systems, vacuum pumps, air compressors, chip trays, carrier plates, instrument racks and much more

Wafer Probe Testing Field Upgradable Features

Modular in design – purchase what you need now, add new capabilities when required

All key building blocks provide selection choices – base, stage, chuck, platen, microscope mount & movement, optics and accessories

Can be configured as a single or multi-application system

Designed to be perpetually field upgraded

Generous module upgrade program significantly reduces the upgrade cost - you trade in your existing module that you don’t need at a prorated depreciation and apply it to your new module(s), saving significant budget.

Device Characterization

RF/High Frequency/Microwave - Get the RF Wafer Probe Testing Guide

High Power - Get the High Power Wafer Probe Testing Guide

Optoelectronics - Get the Optoelectronics Wafer Probe Testing Guide

MEMS - Get the MEMS Wafer Probe Testing Guide

PCB, Displays, Substrates

Automated Systems - Get the Wafer Probe Testing Automation Guide

Individual Die

Partial Wafers

Whole Wafers

Frames - Sawn and Stretched

Packaged Parts

Substrates

Printed Circuit Boards and More...

Device Characterization Wafer Probe Testing Solutions

Device Characterization Wafer Probe Testing Solutions

Optoelectronics Wafer Probe Testing Solutions - LED

MEMS Wafer Probe Testing Solutions - Semiautomatic and Fully Automatic Versions

High Frequency - RF - Wafer Probe Testing Solutions

High Power Wafer Probe Testing Solutions

Magnetic Stimulation Wafer Probe Testing Solutions

Vacuum Wafer Probe Testing Solutions

Low and High Temperature Wafer Probe Testing Solutions

Double Sided Wafer Probe Testing Solutions

Multi-Functional Wafer Probe Testing Solutions

Known Good Die (KGD) Wafer Probe Testing Solutions

The SemiProbe PILOT Control software Suite for SemiProbe semiautomatic and fully automatic probe systems also employs the SemiProbe patented adaptive architecture. Software modules can be added to the base system as needed. PILOT Control Software consists of a Microsoft Windows-based user interface built on the SemiServer application for communicating to and from the probe system. Individual customer applications can be integrated with PILOT Control Software for a more customized system to meet individual needs.

PILOT Control Software comes with standard modules including Navigator and Position Matrix with more sophisticated options like the Wafer Map and Vision module available. Modules interfacing to the SemiServer have a set of remote commands that can be accessed by any other module, providing the capability to perform its own specific function, yet access all other features of the suite seamlessly. Full driver libraries are available for LabView, C++, and Visual Basic with specific instrument drivers to support the most advanced instrumentation available. Communications may be made using RS-232, GPIB or TCP/IP, enabling the system to be either a controller or a slave in an integrated solution.

Lab Assistant Wafer Probe System - 50 mm to 200 mm versions

For a fast response to your inquiry, complete the form to the right and we'll get back to you!